Your Reliable Sintered, Ceramic & Natural Stone Supplier

Our manufacturers Capability enables us to take on any size project

We supply, flooring & wall panels for feature walls, bathrooms, Exterior cladding for Residential & Commercial sector kitchen bench tops and islands

80,000 ㎡

Warehouse Area

4

Intelligent Production Lines

2,500,000 ㎡

Annual Production Capacity

How Is Sintered and Ceramic Stone Made?

As a reliable sintered stone supplier, we control every step of sintered stone manufacturing to bring you excellent quality and durable products.

-

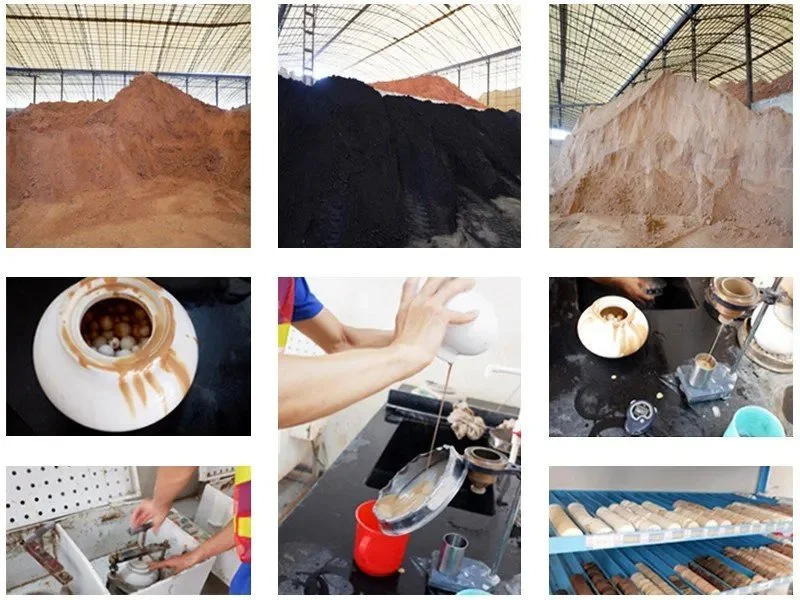

01. Raw Material Testing

The raw materials are tested for their physical properties and suitability for sintering. This ensures that only the finest materials are used in the production of sintered stone, resulting in a superior and reliable end product.

-

02. Chemical Composition Analysis

Through advanced lab techniques, minerals and additives are checked to ensure desired properties like strength, color stability, and chemical resistance, resulting in consistent and quality products.

-

03. Prepare Ingredients

During the production of sintered stone, the ingredients are carefully prepared and measured. This precise preparation ensures that the ingredients are properly mixed and ready for the subsequent stages of the production process.

-

04. Making Slurry Mixture

The natural minerals and additives are carefully measured and introduced into a ball grinder. Then the materials undergo grinding and mixing, along with the addition of water or other liquids. This process transforms the solid raw materials into a smooth and homogenous slurry mixture.

-

05. Slurry Mixture Testing

Samples are taken from the slurry mixture and subjected to various tests, including viscosity, density, and particle size analysis. These tests help assess the homogeneity and flow characteristics of the slurry, ensuring that it meets the required specifications.

-

06. Removing Iron Impurities

The slurry passes through a mesh sieve, allowing the finer particles to flow through while capturing and separating the iron impurities. This sieving step ensures that the slurry used in the production is free from unwanted iron contaminants, resulting in a higher-quality final product.

-

07. Drying Slurry Into Powder

The slurry from the spray tower undergoes drying to transform it into a powder form.The slurry is introduced into a drying system, where it is exposed to controlled heat and airflow. As a result, the moisture content is evaporated, leaving a dry powder material ready for further processing.

-

08. Powder Standing

The powder is stored in a powder silo and left to stand for a specific duration. This standing period allows the powder particles to settle and stabilize, promoting uniformity and ensuring consistent quality. This crucial step ensures that the powder is ready for subsequent pressing.

-

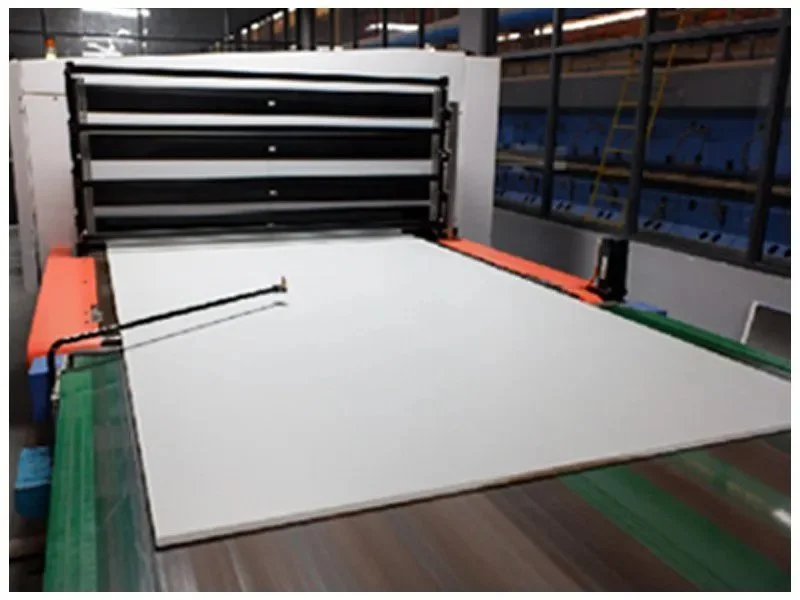

09. Powder Compacting

Sacmi Continua+ is used for compacting the powder. This state-of-the-art technology applies continuous pressure and compaction to the powdered mixture, ensuring precise and uniform compression, resulting in dense and durable body with desired shape and thickness.

-

10. Body Drying

The sintered stone body undergoes a drying process. This involves carefully controlling the temperature and humidity to remove excess moisture from the body, ensuring optimal hardness and strength in the final product.

-

11. Glazing

The glazing process is carried out to enhance the surface appearance and performance of the material. A glaze is applied to the sintered stone body, which is then fired at high temperatures to create a smooth, glossy finish and improve its resistance to stains and scratches.

-

12. Printing

Advanced Sacmi inkjet printing technology enables the application of various designs, patterns, and colors onto the surface of the sintered stone and allows for endless design possibilities, creating visually stunning and personalized sintered stone products.

-

13. Firing In the Kiln

The sintered stone bodies are placed in a kiln for firing, where high temperatures activate binding agents and minerals, fusing them together and forming semi-finished products. This enhances the material's durability, strength, and resistance.

-

14. Semi-finished Products Testing

The semi-finished products undergo testing for color, shape, and thickness. This ensures that the sintered stone slabs meet the desired specifications and quality standards before next stage of production

-

15. Polishing and Edge Grinding

Through advanced machinery and techniques, the sintered stone undergoes a precise polishing process, resulting in a smooth and lustrous finish. Simultaneously, the edges are carefully ground and shaped to achieve the desired profile.

-

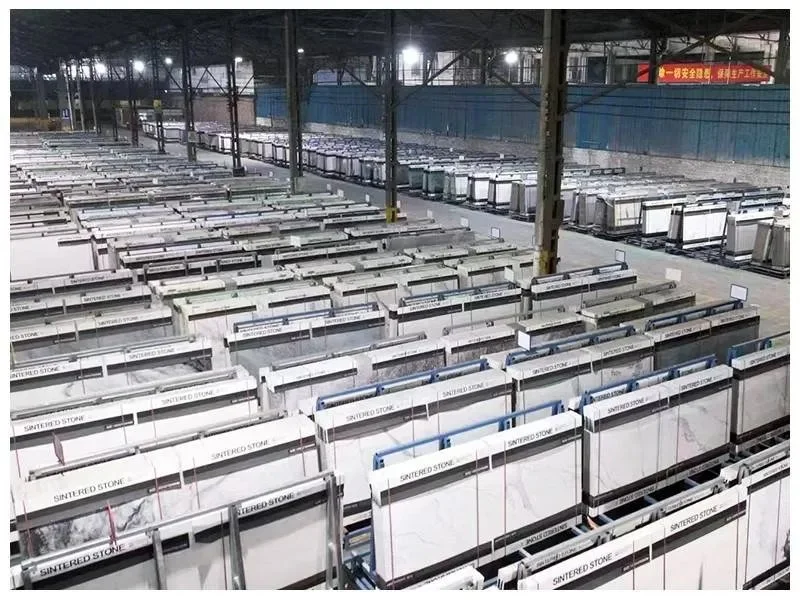

16. Finished Products Packaging

Specialized packaging materials and techniques are used to secure the slabs and prevent any damage during handling and delivery. Proper labeling and documentation are also done to facilitate easy identification and tracking.

-

17. Warehousing

Once packed, the sintered stone slabs are stored in a controlled warehouse. This ensures product quality and integrity, with inventory management systems tracking and organizing slabs for efficient retrieval and distribution upon receiving orders.

-

18. Loading

The sintered stones are carefully loaded into the container and secured with air bags or lashing belt. This ensures safe transportation and protects the sintered stone from any potential damage during transit to clients.